Environment

The continuous evolution of our products is inspired by current regulations, but sometimes we even anticipate the future with innovative product ranges. Today, our offering consists of models with smaller internal volumes, capable of ensuring high levels of efficiency with a substantial reduction of the amount of refrigerant employed. We have also developed a comprehensive range of CO2 models (GWP = 1), capable of operating at ever higher operating pressures. These products can now also be used in regions that are characterized by climates with higher temperatures.

Our units benefit from options and technical solutions that guarantee optimum performance and reduced energy consumption. To check the performance with the new generation low-GWP synthetic or natural refrigerants, we invite you to use our “Scelte” selection program, available at www.modineselect.com/sso. The Scelte selection software is constantly updated with the most significant innovations.

Since September 2015, the Energy related Product (ErP) Directive has specified the rules for setting requirements concerning energy related products, including electric motors used in fans. The main purpose of the ErP directive is to increase the efficiency of the rotor-fan units by 20%.

ECO™ Brand Products

All fans installed on ECO™ heat transfer cooler branded products comply with 2009/125/ec directive of the European Parliament (second stage ErP 2015, energy related products), and have the CE mark as they are manufactured in accordance with the European directives in force. This directive applies to fans with input power between 125 W and 500 kW and is mandatory in all EU countries. The ErP regulation covers products made in the Economic European Area (EEA) as well as imports from non-EU countries. Products being exported from the EU into other countries are not subject to it.

The ErP directive does not apply to products used in ATEX areas, fans used at especially high or low temperatures (< –40°C or > +100°C), fans used in products for short-term emergency use, or fans used in the transportation of people or goods. Modine incorporates all the fans in devices and models ensuring compliance with EU regulation 327/2011. Particular attention has been addressed to the components (fan rings) so as to ensure full respect of directive efficiency and, overall, a perfect balance between air flow performance, energy consumption, and noise level emissions.

*Available in the EMEA region.

What are F-Gases?

Fluorinated (F) gases are man-made gases that can stay in the atmosphere for centuries and contribute to a global greenhouse effect.

Fluorinated (F) gases are man-made gases that can stay in the atmosphere for centuries and contribute to a global greenhouse effect. There are four types: hydrofluorocarbons, perfluorocarbons, sulfur hexafluoride, and nitrogen trifluoride. F-Gas is the term used to describe a particular family of fluorinated gases that are widely used as refrigerants in air conditioning and commercial refrigeration systems (as well as in many essential appliances, such as fire extinguishers and medical inhalers).

Our Product Ranges Meet F-Gas Regulations and Have Been Developed for Present and Future Refrigerants

Modine products have been developed to offer efficient performance and reduced energy consumption, in compliance with the latest F-Gas regulations. Moreover, thanks to a more compact inner volume, our products use less refrigerant charge than in the past. Modine anticipates the future by presenting cutting-edge environmentally friendly solutions!

We’re F-Gas Ready!

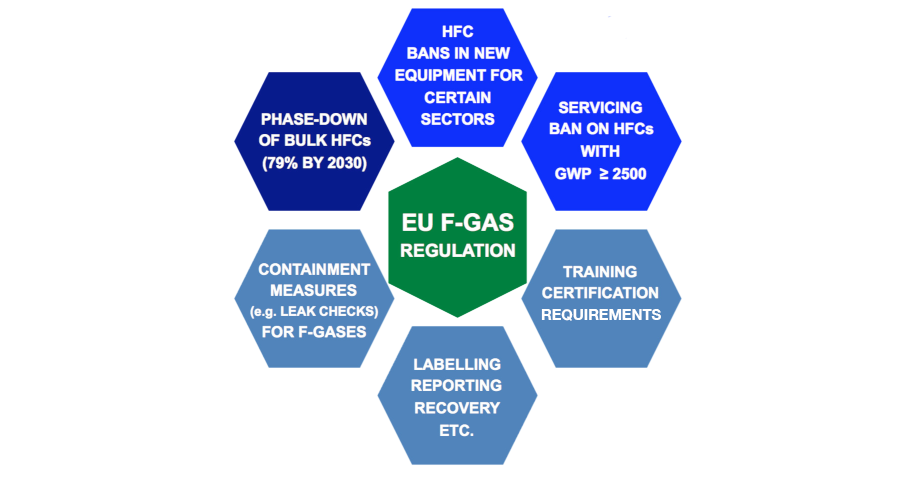

![]() Most of the international scientific community agrees that countries with fossil fuel-based economies are partly responsible for much of global warming. To remedy the negative effects of climate change, the European Commission has launched a program to facilitate the establishment of a more sustainable and efficient economy. This program covers the main economic sectors, including the refrigeration industry. In fact, it also comprises the F-Gas Regulation (EU – No. 517/2014), which aims to drastically reduce emissions of high GWP (Global Warming Potential) fluorinated refrigerants (HFC). The F-Gas regulation imposes the gradual ban of HFCs.

Most of the international scientific community agrees that countries with fossil fuel-based economies are partly responsible for much of global warming. To remedy the negative effects of climate change, the European Commission has launched a program to facilitate the establishment of a more sustainable and efficient economy. This program covers the main economic sectors, including the refrigeration industry. In fact, it also comprises the F-Gas Regulation (EU – No. 517/2014), which aims to drastically reduce emissions of high GWP (Global Warming Potential) fluorinated refrigerants (HFC). The F-Gas regulation imposes the gradual ban of HFCs.

The Fluorinated Gas Partnership Programs were launched as a joint effort by EPA and industry groups to reduce the amount of fluorinated gases (F-Gas) emitted from a variety of industrial processes. The programs promote the development and adoption of cost-effective F-Gas emission reduction opportunities.

The refrigeration industry is reacting to this significant change by introducing new technologies and adopting innovative designs for the development of refrigeration installations.

The entire sector is rapidly evolving – from HFC producers to equipment manufacturers, installers, production plant management and maintenance operators. Starting from 2018, as a result of the F-Gas Regulation, the quantities of HFC available on the EU market will be limited. The reduction process, called “HFC phase-down,” is based on a quota system specified by a CO2 equivalent.

The HFC restrictions will concern:

- From January 2020, permanent refrigeration equipment containing HFC with GWP greater than or equal to 2500.

- From January 2022, commercial “multipack” refrigeration systems with a nominal capacity of or exceeding 40 kW, containing fluorinated gases with GWP equal to or greater than 150.

All manufacturers of refrigeration systems are therefore involved. The continuous evolution of our products is inspired by current regulations, but sometimes we even anticipate the future with innovative product ranges. Today, our offering consists of models with smaller internal volumes, capable of ensuring high levels of efficiency with a substantial reduction of the amount of refrigerant employed. We have also developed a comprehensive range of CO2 models (GWP = 1), capable of operating at ever higher operating pressures.

These products can now also be used in regions that are characterized by climates with higher temperatures. Our units benefit from options and technical solutions that guarantee optimum performance and reduced energy consumption.